-

Serie 1 - Generic Material

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

-

-

Serie 2 - Composite

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

-

Serie 3 - Generic Routing

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

-

Serie 4 - Furniture

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

-

Serie 5 - Part Of and Finisihing

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

- Join this Course to access resources

- Quiz

-

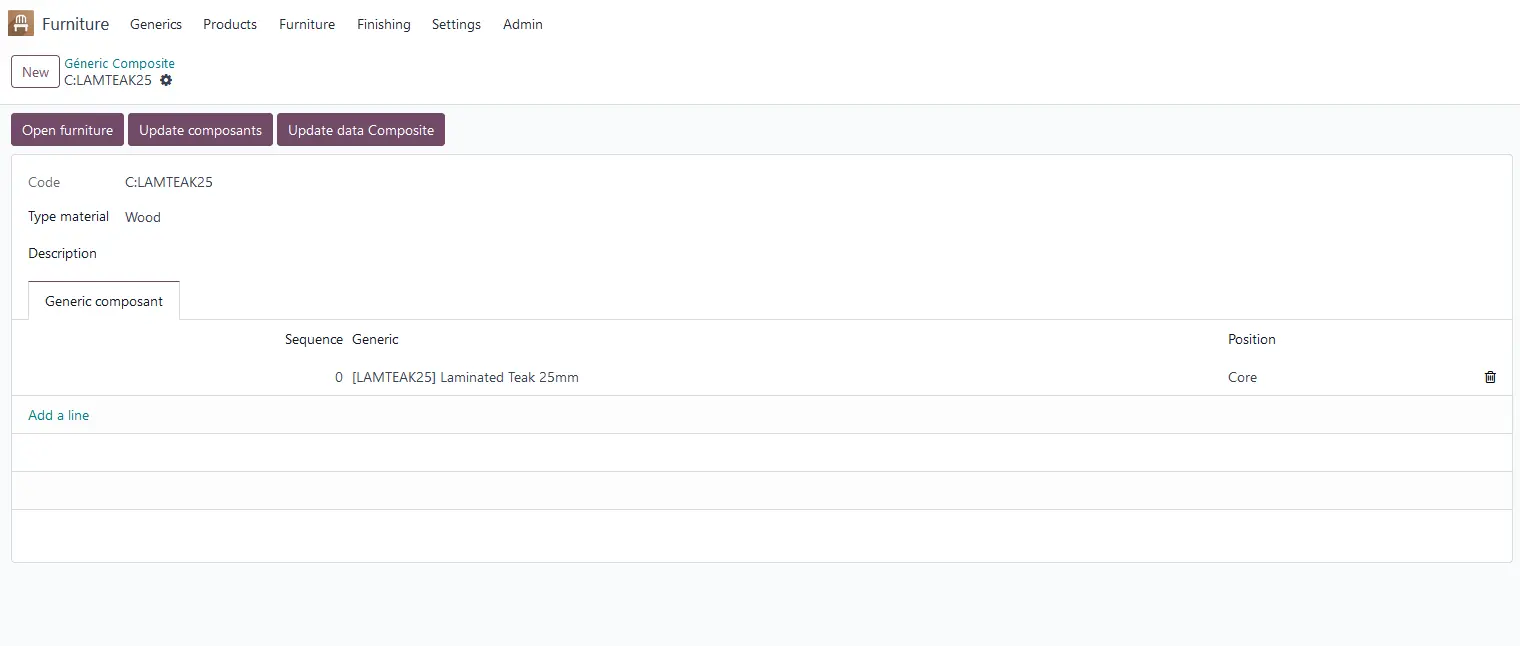

- Introducing Composite

Introduction to Generic Composite in Furniture Manufacturing

In the world of furniture manufacturing, customization and flexibility are key factors in creating products that meet diverse customer needs. One way to achieve this is by using a Generic Composite system, which allows for the efficient combination of various materials and components to produce a finished product. This article introduces the concept of Generic Composite and its implementation in a structured furniture module.

What is Generic Composite?

A Generic Composite is a configuration that combines several Generic Materials, such as boards, accessories, and other components, to create a complete product. Each composite is built using a predefined structure, allowing manufacturers to design flexible and customizable furniture.

Key Features of Generic Composite

- Modularity: Components can be added, removed, or replaced to meet specific needs.

- Flexibility: Various materials can be combined to create a range of designs.

- Structured Data: Each composite is organized systematically to ensure consistency and accuracy.

Struktur Generic Composite

The Generic Composite system includes a model line called Generic Composant, which serves as the building block of the composite. This line contains detailed information about the components used. Below are the main columns in Generic Composant:

1. Sequence

Indicates the order in which components are added to the composite. This ensures proper arrangement and prioritization during assembly.

2. Generic

Refers to the Generic Material (e.g., board or accessory) used in the composite. This column links each composant to a specific product in inventory.

3. Position

Defines the role of the material in the composite. Common positions include:

- Core: The main element of the composite, often providing structural strength.

- Top: The upper surface, such as the top of a table.

- Bottom: The lower surface or base.

- Edge: Components that form the edge, often for decorative or protective purposes.

Example of Usage

For example, designing a modular table using the Generic Composite approach:

- Core: High-strength board as the foundation of the table.

- Top: Polished wood sheet as the tabletop.

- Edge: Decorative trim to enhance aesthetic appeal.

By defining each part with a specific position, the assembly process becomes simpler, and modifications can be made easily.

Benefits of Using Generic Composite

- Efficiency: Streamlines the production process by organizing components systematically.

- Customization: Allows manufacturers to tailor products to meet customer needs.

- Scalability: Facilitates the creation of various furniture models from a set of standard components.

Conclusion

The Generic Composite system is a powerful approach in furniture manufacturing, providing flexibility, efficiency, and customization. By leveraging this structured model, manufacturers can optimize their production processes and deliver high-quality products tailored to customers.

Whether you are designing a simple chair or a complex modular wardrobe, the Generic Composite system provides the tools needed to bring your vision to life.

There are no comments for now.